Despite having a clearout of cameras, I did recently buy another! This is a whole-plate tailboard camera that I wanted for the impending wet-plate season. It was advertised on ebay, reasonable starting price, and I was the only bidder.

The camera came with three double darkslides, a T-P rollerblind shutter and an un-named 10” f/8 Rapid Rectilinear lens, all in pretty good condition. There are no seperate lens panels, the camera can have only a single flange on it.

As I have two lenses very suitable for wetplate work, I decided to work out how to fit them. One is a 3D Dallmeyer Patent Portrait lens f/6 and the other is a Ross Extra Rapid Symmetrical f/4. Both have their own flanges: neither lens will fit the other’s flange even though it is very close. I also decided that it would be nice to still be able to use the lens that came with the camera.

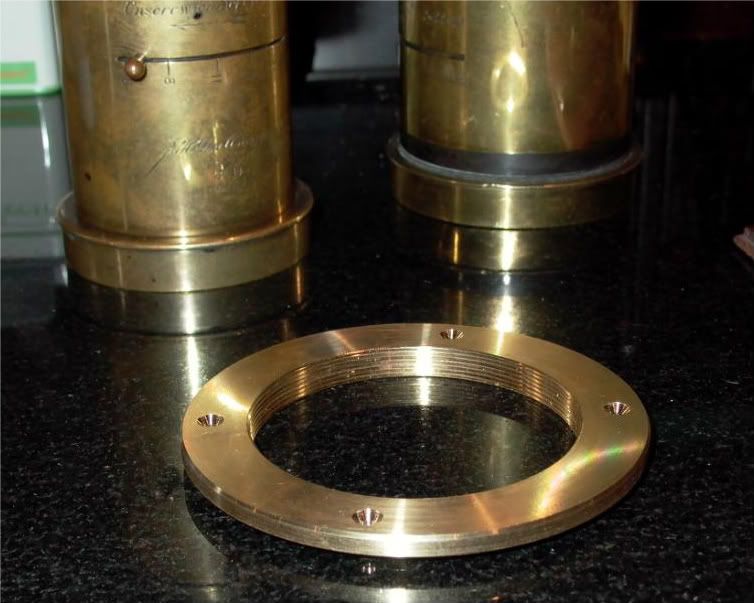

I happened to chance on the fact in the 1880’s the RPS made a recommendation that lenses with a mounting diameter below three inches should have a thread of 24TPI (turns per inch). On checking with a thread gauge, I found that my two lenses did indeed have the same pitch thread, and that the Ross was only about 1/32” larger. As there was enough brass on the mounting , I decided to re-cut the thread to the same diameter as the Dallmeyer. As the Dallmeyer flange needs a hole 4-1/4” diameter, I decided to make a new flange to screw to the camera that would accept both lenses, and then make a reducing ring to fit the original f/8 lens. The new flange only needs a hole 2-7/8” diameter.

As I only thought of writing this after I had started, the first couple of photos shew the reducing ring being started, but the main flange was done the same way!

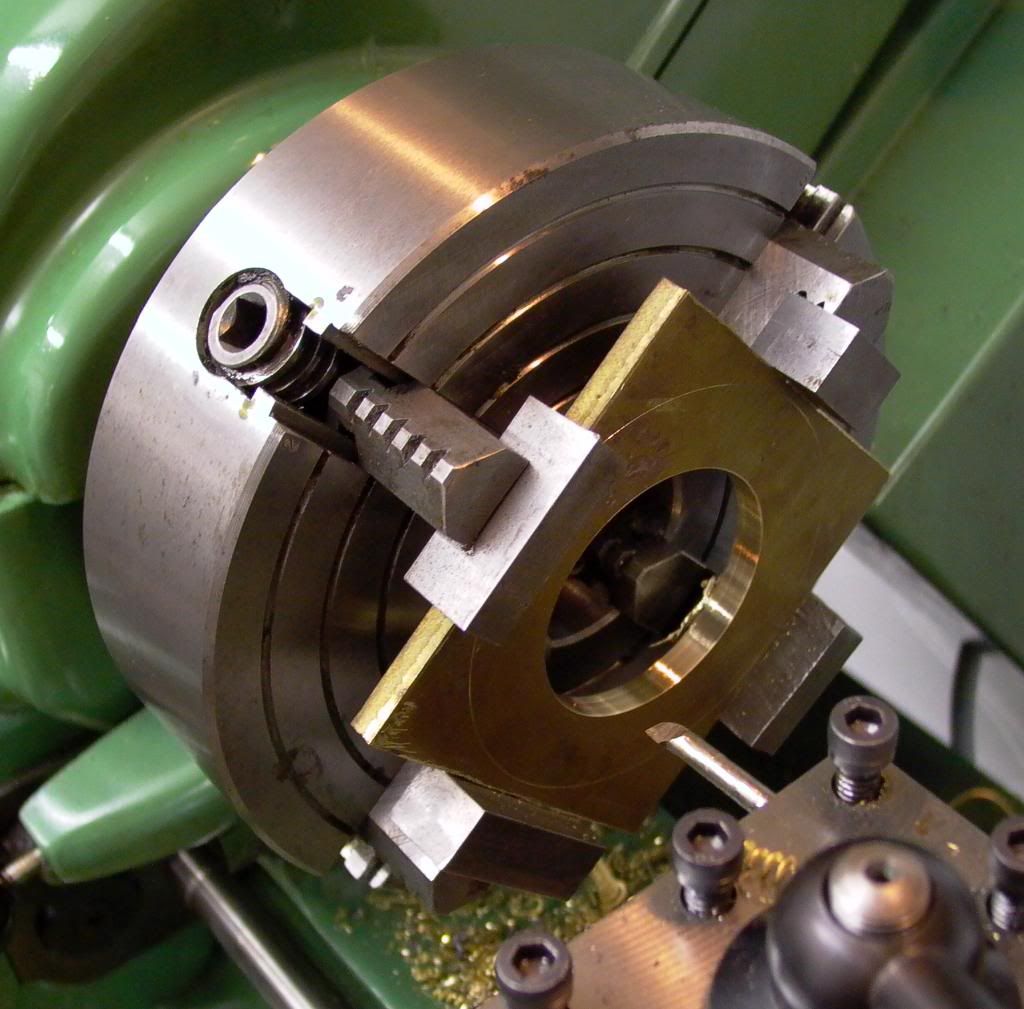

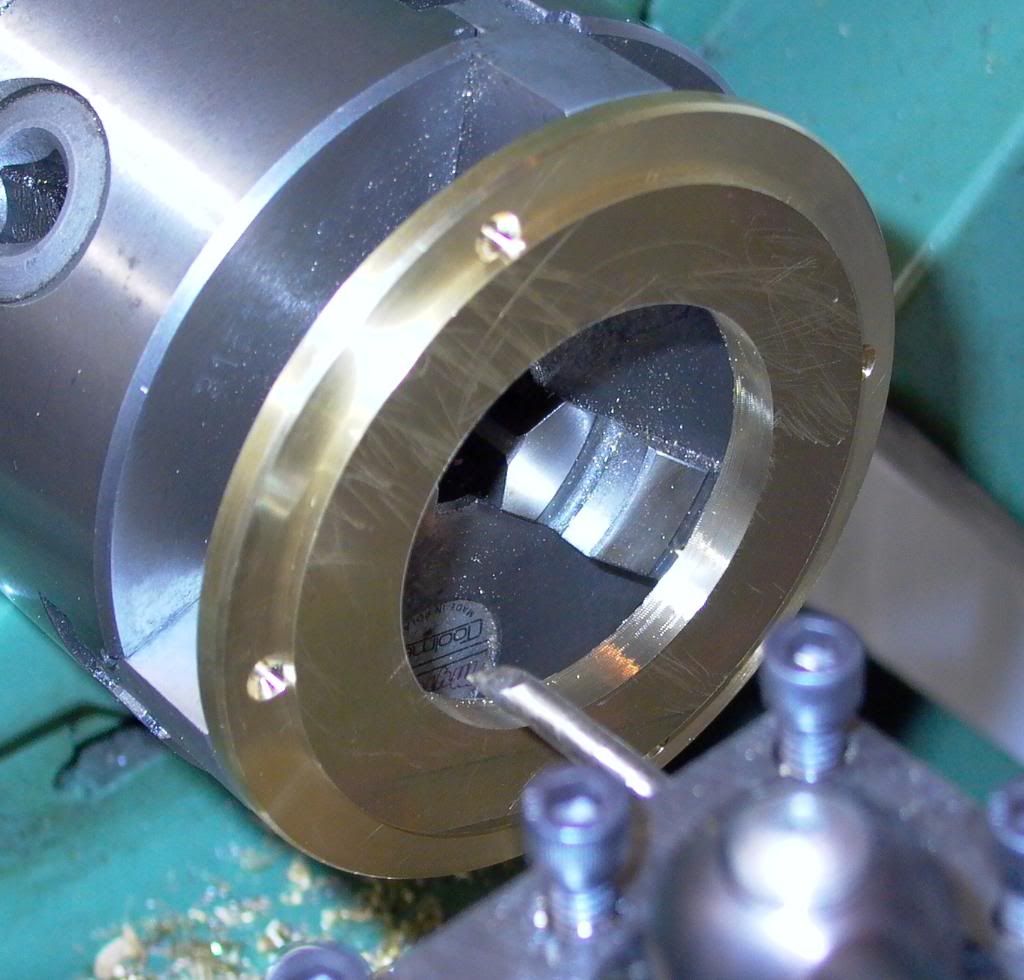

A piece of plate brass was set up in the four-jaw chuck in the lathe:

It was then drilled and bored out to a bit under the finished size:

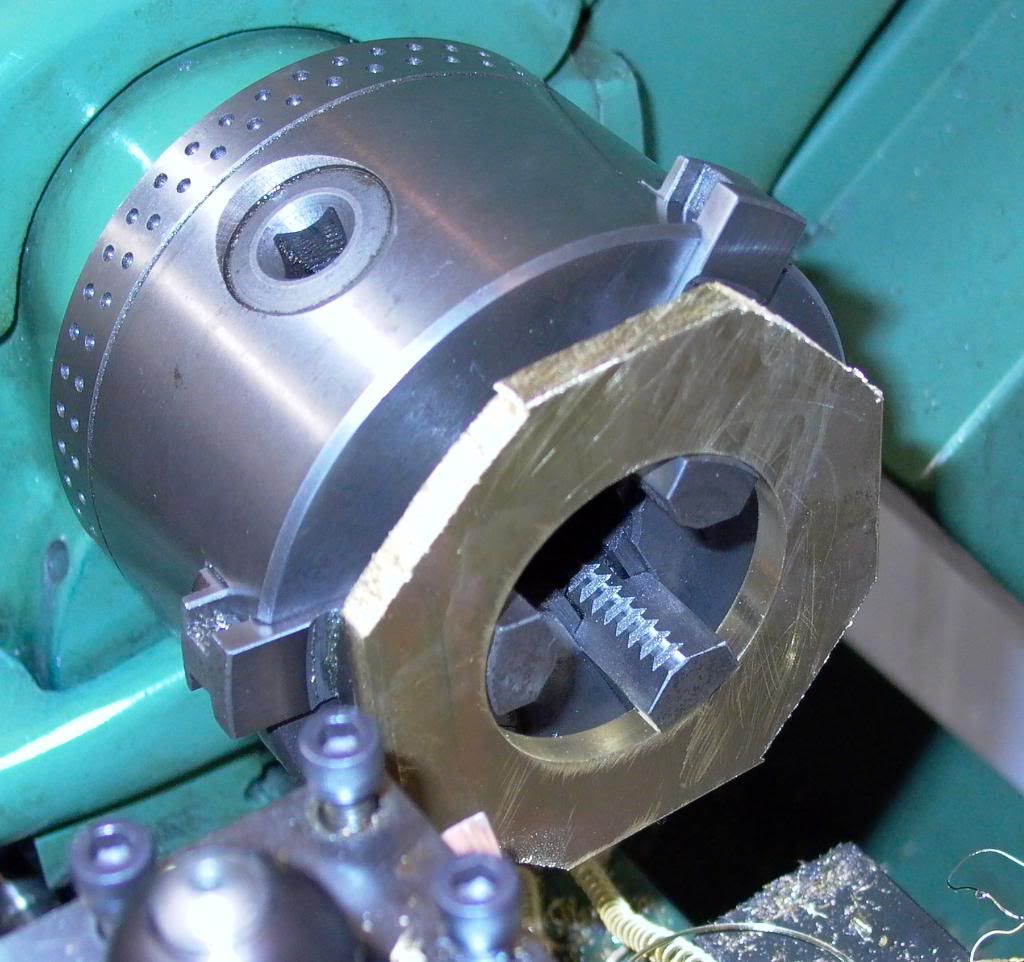

The corners were then sawn off and the piece mounted by the hole in the three-jaw self-centering chuck:

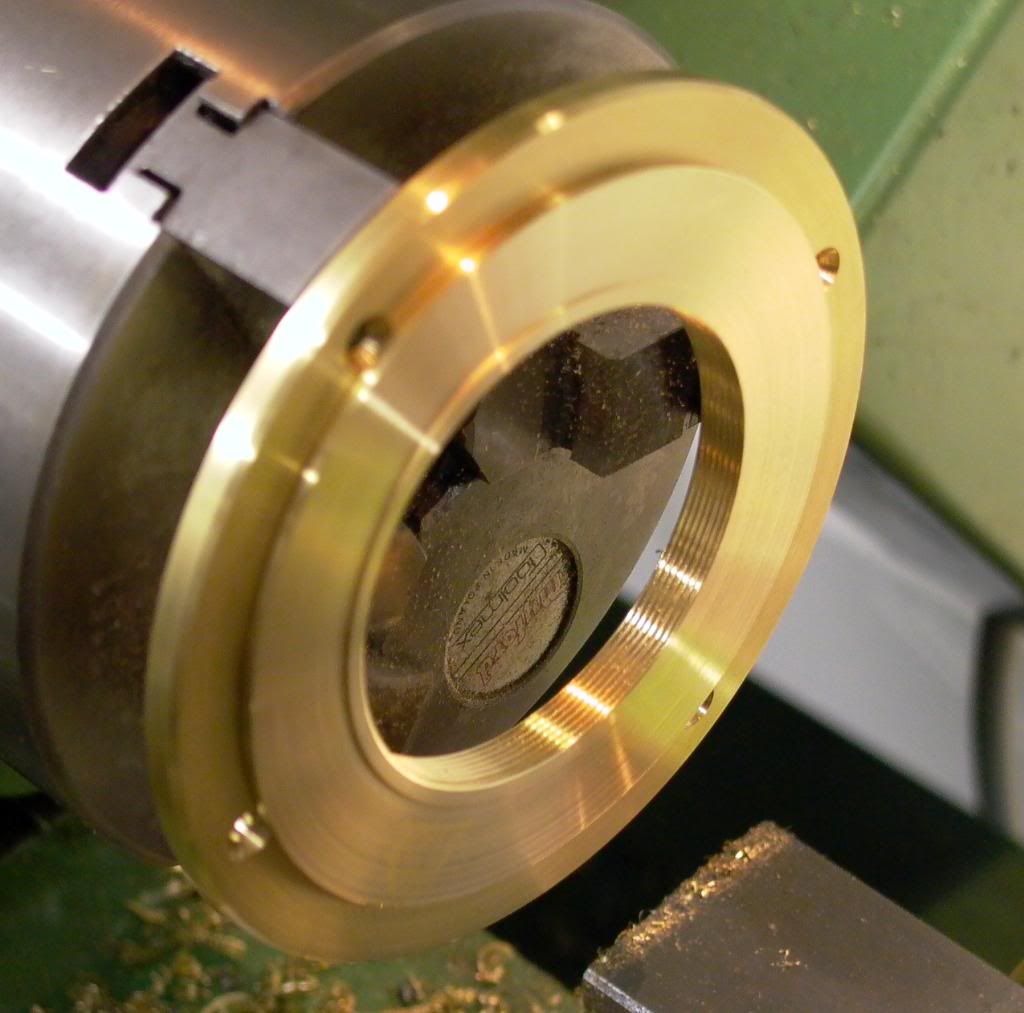

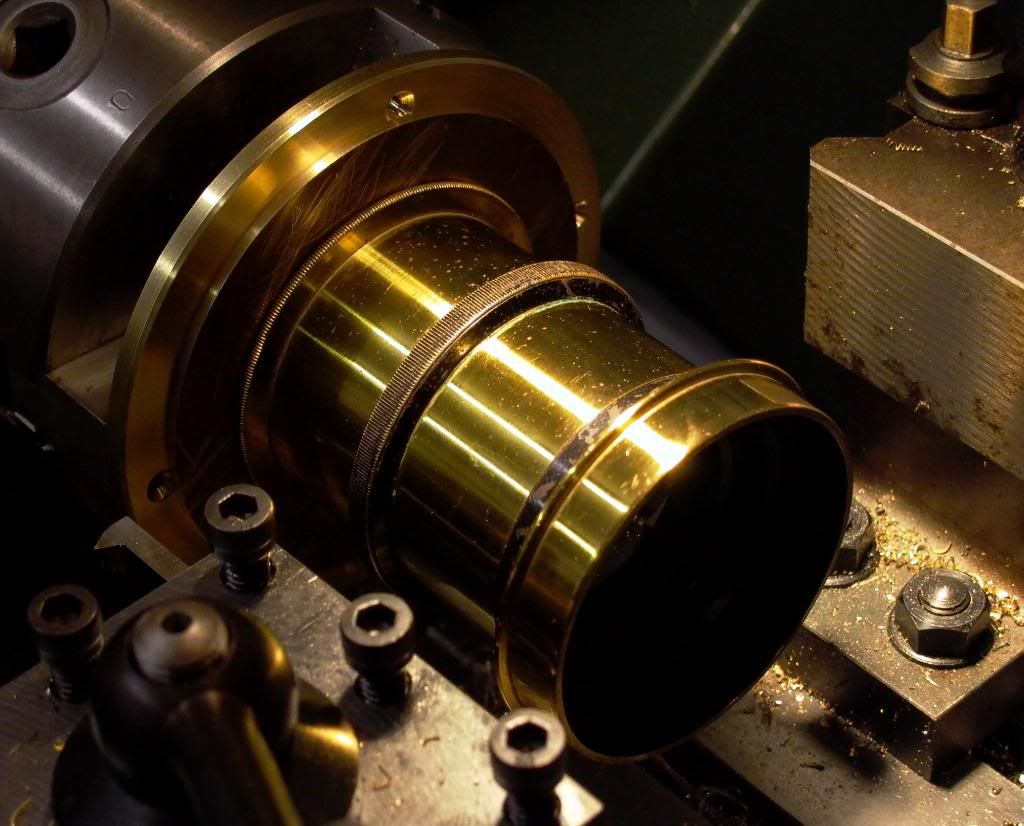

And the outside turned to diameter, including the spigot to fit in the hole in the wooden front of the camera. Here it is supported by the adaptor flange.

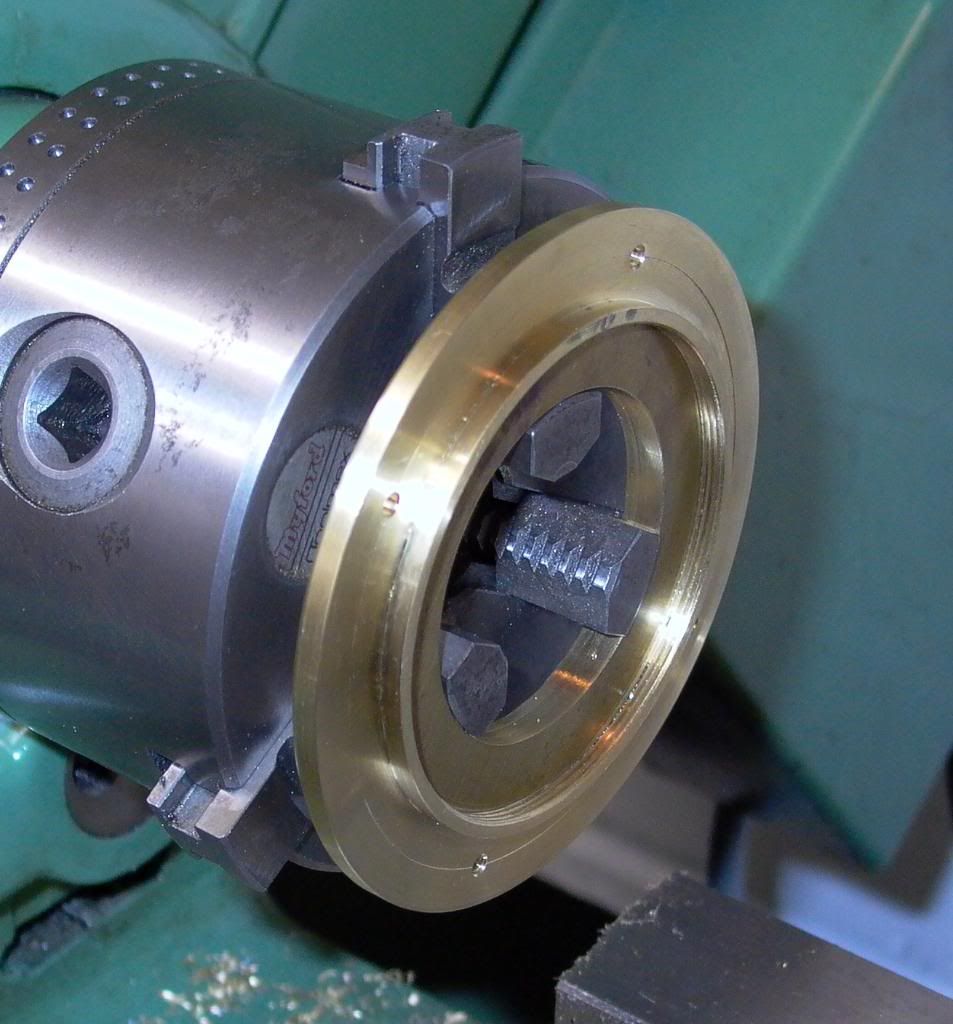

Then, holding it by the outside, the thread was cut. Here is a picture of the flange completed.

The Ross lens was then dismantled and the mounting thread cut to match the Dallmeyer.

The adaptor flange was then made:

The brass blank, turned, rough-bored and screw-cut to match the Dallmeyer, was then screwed in to the flange, which acted as a holder for it for boring to size:

And screw-cutting to the akward pitch of 30 TPI:

The new flange beith tried for size:

Susie